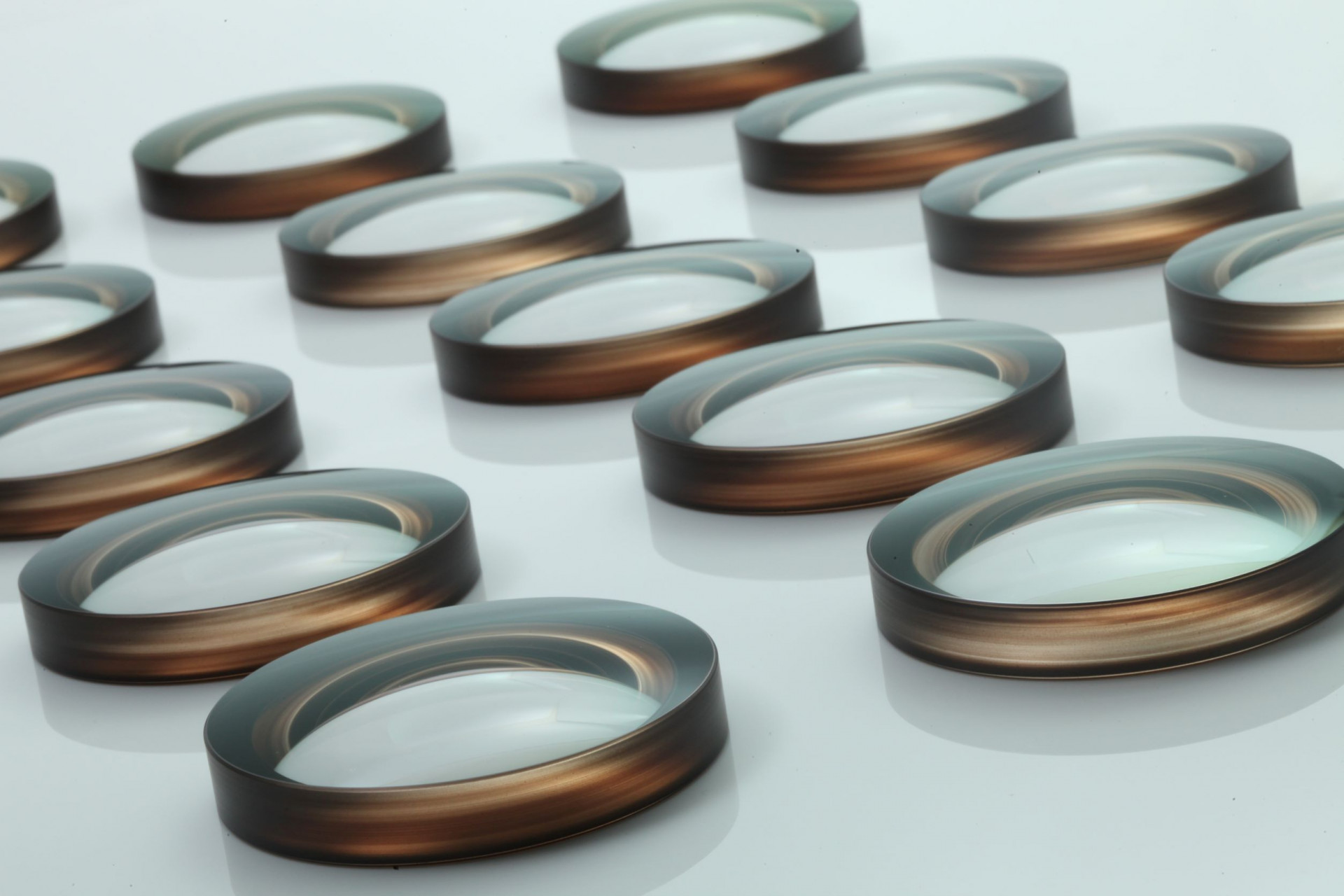

Glass Grinding

Glass lenses reduce anti-reflection and block optical noise through multiple processes of cutting,

grinding, polishing, centering, coating and inking.

Currently, such glass lenses are the mainstream of the market.

Glass material -> Milling -> Grinding -> Polishing -> Centering -> PVD (Coating) -> Bonding/Inking

grinding, polishing, centering, coating and inking.

Currently, such glass lenses are the mainstream of the market.

Glass material -> Milling -> Grinding -> Polishing -> Centering -> PVD (Coating) -> Bonding/Inking

Product Specifications

| Processing | Capability |

|---|---|

| Grinding Processing Precision | Newton's Rings ±2本(AS1/4λ) Thickness Tolerance ±0.02mm |

| Processing Precision | Diameter Tolerance ±0.005mm Centering Error30'' Z-Value>0.08 Polygon、D-Cut。 |

| Coating | Processing Precision/ R max ≦ 0.2 % 440 ~ 650nm Broad Band A.R(425 – 1000nm) R max < 1.1%, R ave < 0.8% 430 ~ 620mm T ave ≥ 97% T ave ≦ 1% at 700nm ~ 1100nm T min ≥ 92%,T=50%, at 650 ± 5nm ML coater with 70+ layers capability |

| Coating Machine | Crystal & optical monitor ML Coater with Ion-source assistance |

| Inking | Lens Single, Doublet, Triplet |

Contact