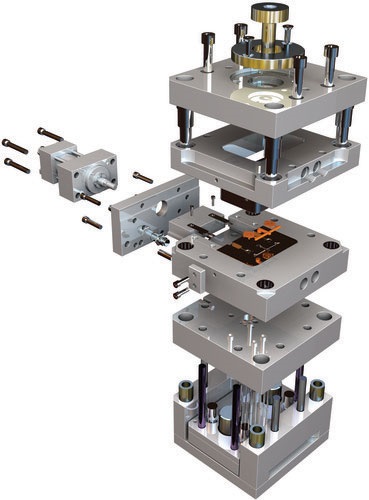

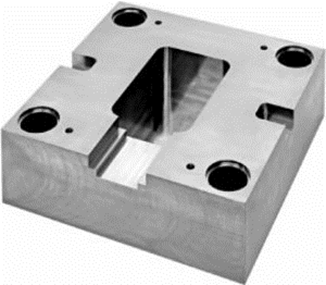

Mold development design and production

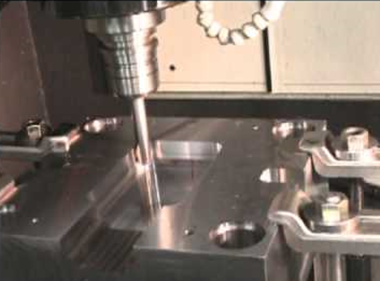

1. Processing equipment with the best precision and stability in the industry.

2. Equipped with small and high-precision 3-D measurement equipment.

3. Equipped with high-precision on-board measuring instrument with an inner and outer diameter of 0.3 um accuracy.

4. Possess nano-level turning and grinding equipment and technology.

5. Partner with many external tooling base and part suppliers with long-term excellent cooperation.

6. Ability to design slide tube.

7. Moldex mold flow analysis software.

8. Apply the precise design software UG (Unigraphics NX) for tooling design.

9. Integrate tooling design with the machining program (UG Cam) to gain better machining accuracy.| Machine | Machining Accuracy | Machining |

|---|---|---|

| CNC Milling machine | 0.0030 | External dimensions milling |

| CNC Milling machine | 0.0010 | External dimensions milling |

| Electrical Discharge Machining(EDM) | 0.0040 | Larger size metal discharges |

| Electrical Discharge Machining(EDM) | 0.0020 | Smaller, high-precision metal discharge |

| Ultra-precision processing machine | 0.0001 | Tungsten steel mold core aspheric surface processing Ultra-precision machining and grinding |

| Ultra-precision processing machine | 0.0001 | Nickel layer mold core aspheric surface processing Ultra-precision machine turning |

| JG Grinder | 0.0020 | Template drilling and shape grinding |

| Internal and cylindrical grinder | 0.0010 | Inner and outer circle, and special-shape grinding |

| NC surface grinder | 0.0020 | Flatness, parallelism and surface grinding |

Product Specifications

Contact